Creating the Future of Intelligent Manufacturing, Wings Taking Flight — Tia Digital Science Collaborates with COMAC C919 to Lead a Revolution in New-Quality Production Power in Aerospace

In this era full of transformation and innovation, we are fortunate to witness the rise of Chinese intelligent manufacturing, especially in the strategic field of the aerospace industry. Today, we tell a story about dreams, innovation, and strength—this is not just about an aircraft but a legend of Chinese manufacturing and a nation's heavy-duty equipment.

The name C919, carrying the dreams and expectations of the nation, represents China’s independently developed new generation large passenger aircraft and is a shining achievement of major national science and technology projects. General Secretary Xi Jinping praised the large aircraft at the 19th Academician Conference of the Chinese Academy of Sciences and the 14th Academician Conference of the Chinese Academy of Engineering, emphasizing: “We focus on leading the industry towards mid-to-high-end levels, and accelerate the catch-up to international advanced standards with projects like the C919.” This not only affirms the C919 but also expresses high hopes and expectations for China’s aerospace industry.

The development and manufacturing of the C919 reflect China’s independent innovation capability and symbolize the country’s comprehensive strength. It carries the dream of hundreds of millions of Chinese to fly and shoulders the historic mission of transforming China from an economic powerhouse into a military stronghold.

As a subsidiary of Silkroad Visual, Theia Digital Technology has been committed to promoting industrial upgrading and social development through digital technology. The company boasts a team of top domestic talents and owns multiple core technologies, making it an outstanding enterprise in the field of digital twin technology in China.

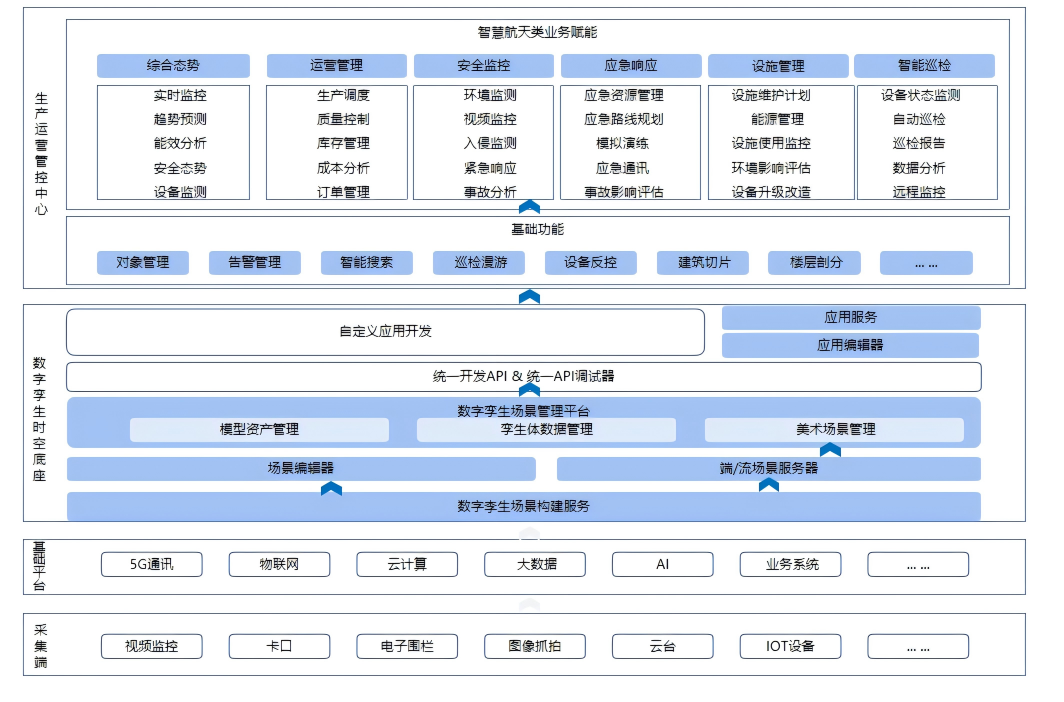

In the COMAC C919 project, Theia provided a brand-new intelligent control platform through digital twin technology for COMAC. This platform integrates virtual and real data, multi-source heterogeneous data, simulation, and data-driven analysis, enabling real-time monitoring of production processes, data analysis, and decision support. This significantly improved production efficiency and product quality. Our technology not only optimized COMAC’s manufacturing processes but also enhanced the market competitiveness of the products.

The project is data-centric, providing precise analysis and comprehensive judgment for COMAC’s operations through deep processing and multi-dimensional mining. This is not just technological innovation but a deep integration of business logic, allowing data to “speak” and strongly supporting decision-making.

We adopted the most advanced digital twin technology to transform complex production data into intuitive graphics, allowing decision-makers to grasp production progress and quality control at a glance. This deep business logic integration improves decision-making efficiency and accuracy, bringing revolutionary changes to COMAC.

Traditional production management relies on manual data collection and analysis, which is inefficient and error-prone. The application of digital twin technology makes production management smarter and more automated. It monitors production data in real time, automatically detects problems, and proposes solutions, greatly enhancing efficiency and quality.

The nerve center of the COMAC C919 project, integrating data related to production, management, and safety through intelligent analysis, providing a comprehensive view of operations. It monitors progress in real time and predicts potential risks, offering strong decision support.

Comprehensive Operation View:Integrates multiple data sources for real-time monitoring and risk prediction.

Real-time Monitoring and Decision Support: Ensures smooth production execution through real-time oversight and proactive risk management.

Based on the twin scene platform, this center offers a fully computer-generated, modernized digital factory with real-time geographic simulation and interaction. It allows production managers to monitor the operation of assembly lines in real time, quickly identify and resolve issues, and greatly improve efficiency and product quality.

Digital Factory:Achieves real-time geospatial simulation and interaction, enhancing management capabilities.

Efficiency and Quality Improvement: Ensures smooth project progress with real-time data.

This center supports over a dozen industry application projects, including strategic goals and annual operational plans, promoting data resource integration. It enables data-driven decision-making and strategic planning from a comprehensive perspective.

Data-Driven Decisions:Facilitates holistic management with integrated data for strategic and operational support.

Strategic and Daily Management: Ensures goal achievement and operational efficiency.

Through real-time video streaming and twin scene display, this center enables comprehensive monitoring of every corner of the factory, improving emergency response capabilities. Advanced surveillance and data analysis ensure safety and environmental protection, providing a solid safeguard for the project.

Full Monitoring: Achieved via live video and twin scene visualization.

Safety and Environmental Assurance: Ensures safe and eco-friendly operations, supporting the smooth progress of the C919 project.

Overall Digital Twin Framework: Built on carefully designed data processing, graphics mapping, visualization, and auxiliary modules, creating a bridge that systematically organizes, analyzes, and transforms complex production data. Using precise algorithms and intelligent mapping, it visualizes abstract data into intuitive graphics with dynamic effects, breaking down barriers to understanding data and making key information immediately clear. This transformation not only visualizes data but also enables decision-makers to quickly grasp core insights and make more efficient, scientific decisions, elevating production and operational management.

Visual Component Design:Features a deep blue visual theme, reflecting the profound and steady qualities of the aerospace industry while creating a calm, professional atmosphere. Innovative integration of 3D scene animations with dynamic data displays aligns with production data needs and enhances usability and interactivity across various business scenarios. Additionally, diverse chart forms such as bar, line, pie, and trend charts transform dull data into vivid visual presentations, uncovering hidden logical relationships and supporting efficient decision-making for aerospace development.

3D Models and Dynamic Displays: Leveraging Tia Engine’s powerful capabilities, detailed 3D models of equipment within the park are constructed, providing immersive 360° views. It also bridges departmental and system silos, ensuring real-time, accurate data extraction and processing, and through fusion with 3D models, achieves dynamic visualization for intuitive, comprehensive park management and operations.

Real-Time Data Integration and Display: Using cutting-edge digital twin technology, we have built a highly realistic virtual space that supports dynamic visualization of complex parameters across various aircraft models and massive production data. This breakthrough acts as the “real-time eye” of the security and environmental control center, enabling precise, continuous display of equipment and personnel locations, providing a solid data basis for safety management and environmental decisions, significantly improving control efficiency and ensuring the entire production remains manageable and efficient.

The operation and management of the C919 production not only witness the birth of a national powerful aircraft but also experience the transformation of new-quality production power. Every technological innovation here is a pursuit of dreams, and every data heartbeat is a promise for the future. Heavy-duty equipment, intelligent manufacturing the future—powered by technology, we are writing a new chapter in China’s aerospace industry!

Theia’s technological strength and industry influence extend beyond aerospace. We have successful cases in intelligent manufacturing, emergency response, space, and maritime industries. Our technologies help clients deeply mine data and realize value transformation, making new-quality production power visible and promoting industry digital transformation.